Based on 4 service modules

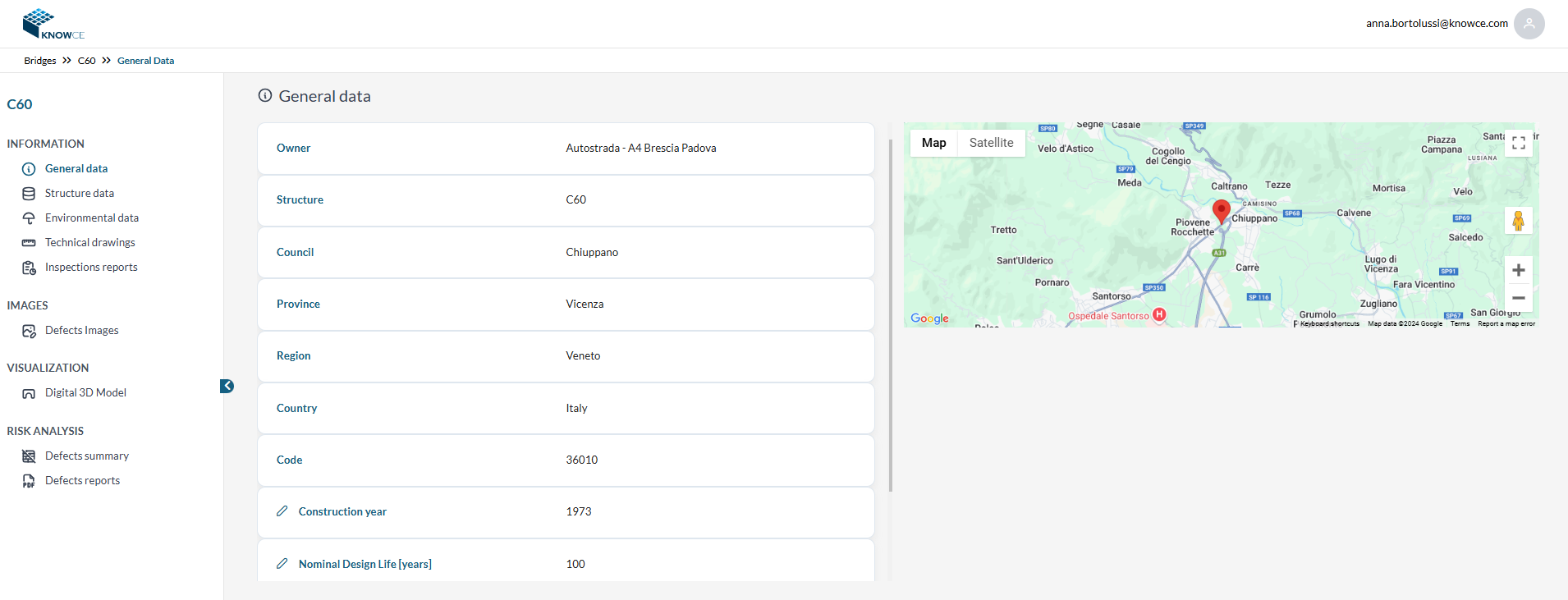

Digital library

Reports the main information about the analized structure as the Owner, the location and the year of construction. It includes environmental and weather information based on bridge location.

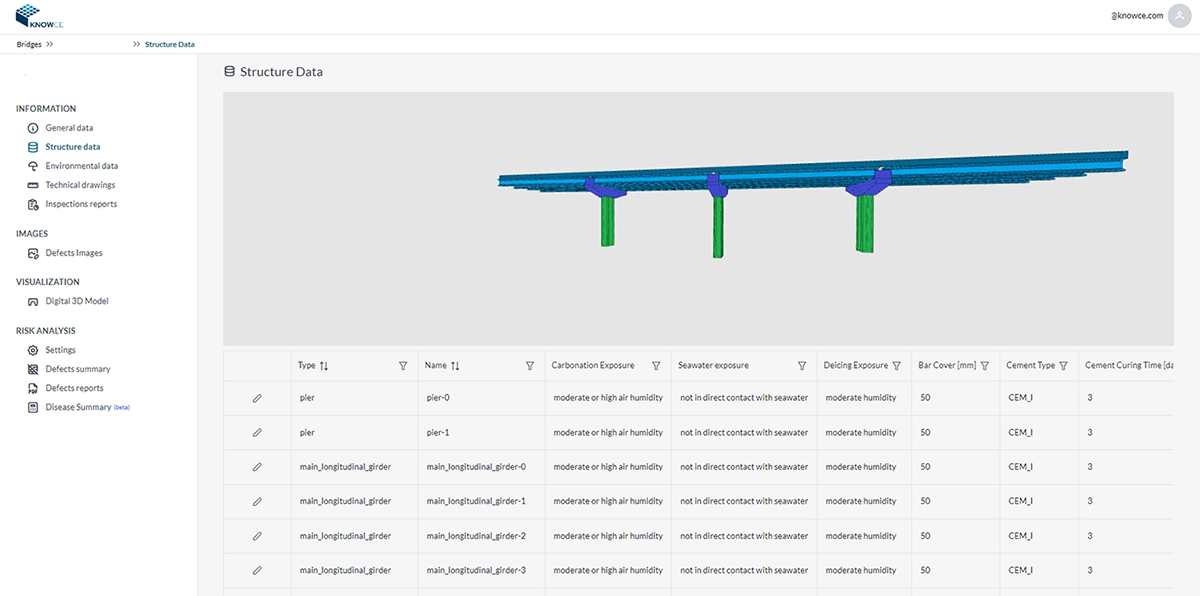

Digital Twin

Digital library of the structure, including design report and drawings, the BIM simplified model, past and present inspection reports, weather conditions in the last 60 years, 3D photogrammetric model and set of images of the structure with 3D positioning.

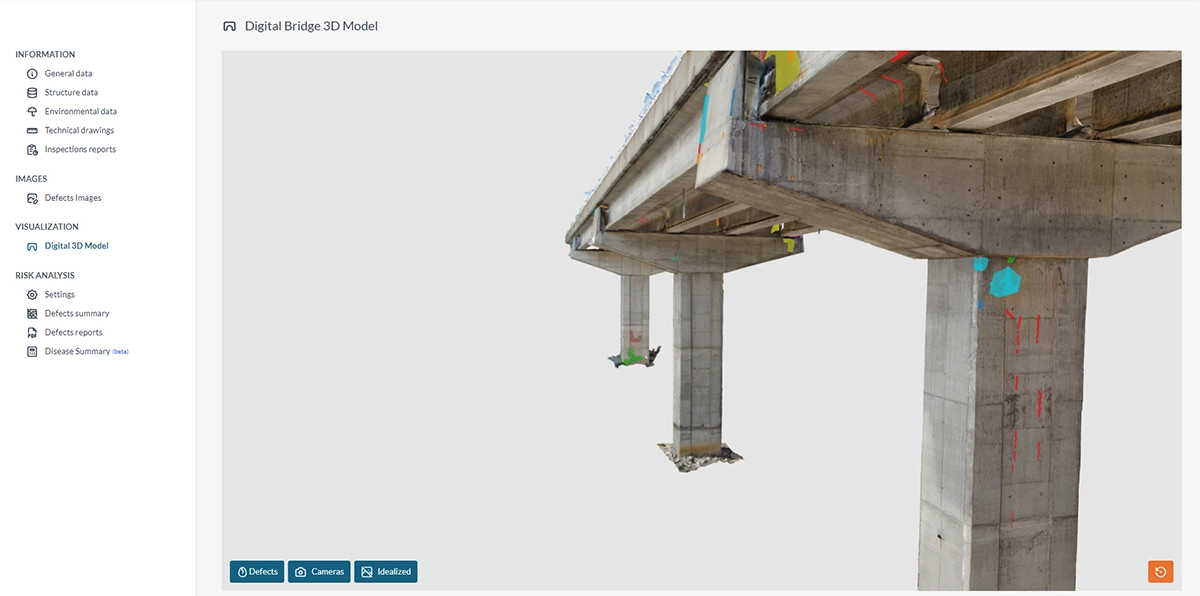

Digital Inspection

Defects identification and positioning within the 3D model through proprietary A.I. algorithm and collection of pictures used for the defects analysis and with the final defect report.

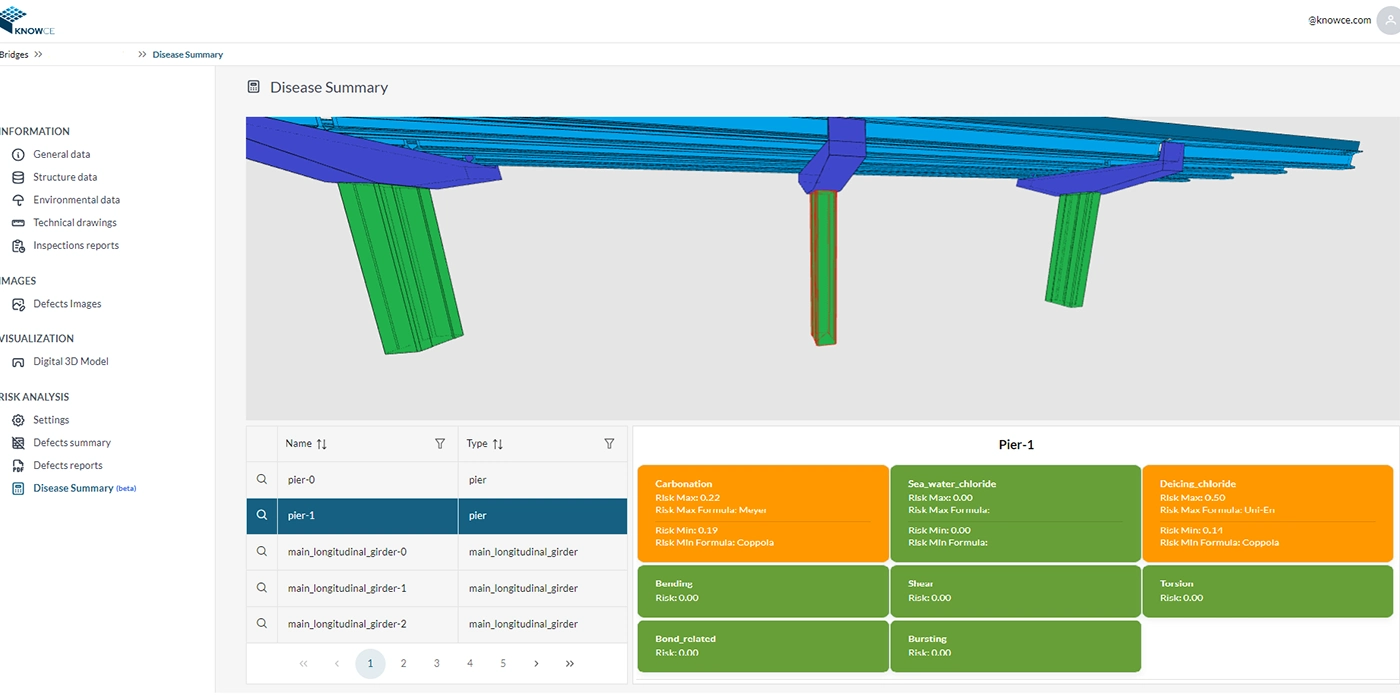

Digital Assessment

Structural assessment of each defect, with risk classification for engineering review, developed using the most known and agreed international standards and formulas about concrete ageing, damaging and danger/risk.

Digital Maintenance

Tracking of required inspection timeframe and ability to log performance of maintenance and automatic generation of the maintenance contract templates from the annotated BIM model.

Coming soon.

A four step process to ensure systematic, high quality inspections

A four-step process designed to elevate quality and efficiency. From initial data capture to expert engineering review, each phase seamlessly integrates cutting-edge technologies.