BRIDGING THE GAP WITH A.I.

The management team is supported by a Board with deep Industry and Technology experience

OUR JOURNEY

Our journey started with an idea: to provide to infrastructural owner and to their technical staff, or to their engineering services supplier, an innovative and A.I.-driven software to speed up inspections and structural assessments.

Our Founders knew that the world of structural engineering has always seen experts stripped of their goggles, jacket and calculation tools to go out into the field, equipped with pen and paper and relying on their experience and patience to endure inspections in every season and even the most adverse conditions.

The health and safety control of structures and buildings has buildings has seen, over the decades, the placing in the hands of technicians of more sophisticated, capable and smart tools while remaining their feet in the mud, in the water because they were in close proximity to the works they were they were monitoring.

Even the introduction of IOT technology, with sophisticated monitoring devices, fails to ensure the true minimise the time to be spent on field checks, because images and tests are to be carried out in situ, as almost all of national regulations mandatorily requires.

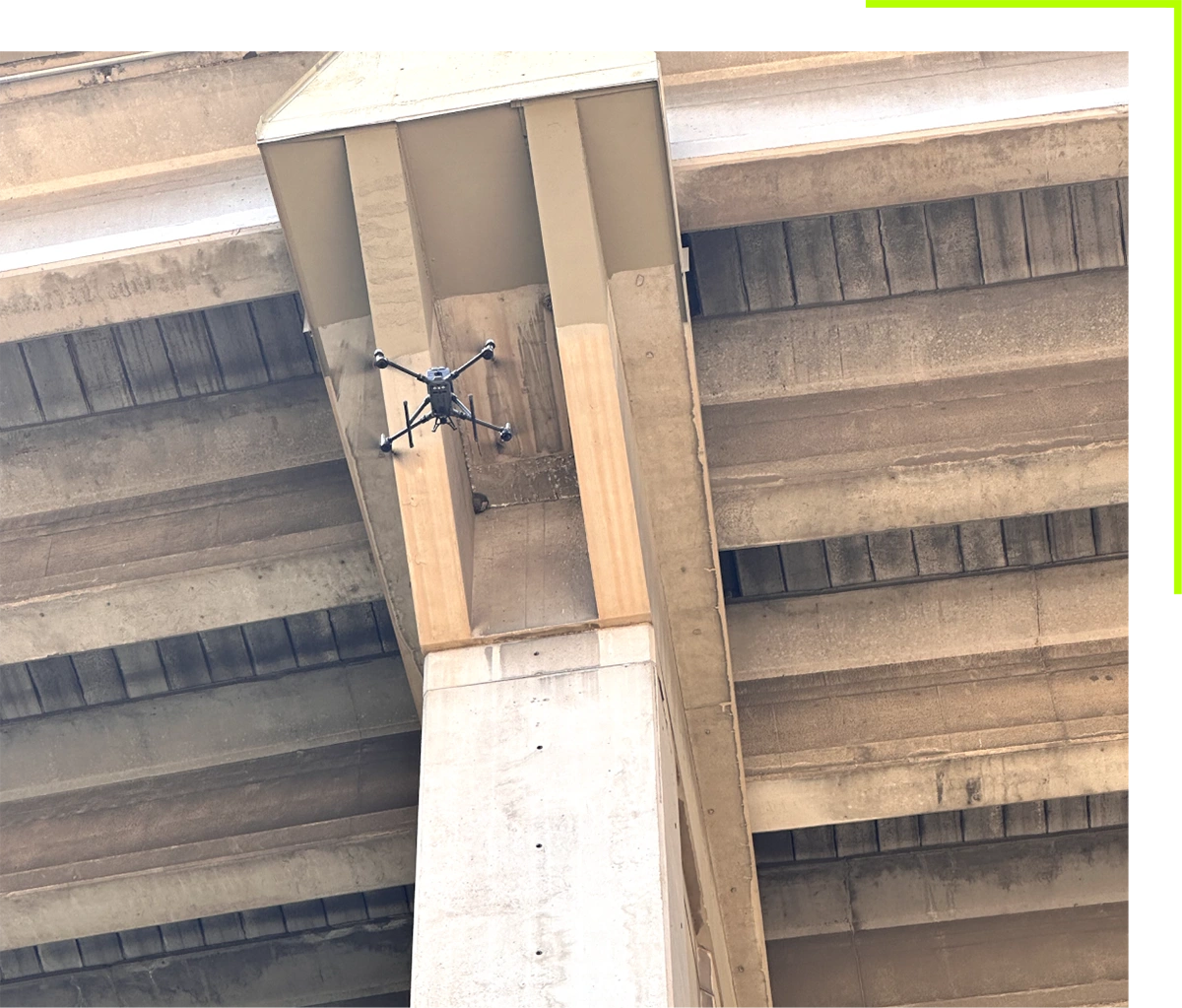

A new and modern tool is needed, engineers and their team have no more time to waste in ordinary inspections on site, new technologies can now be applied for high quality images and structures’ defects reporting.

The software CEA, developed with the support of technicians and engineers who for decades have deployed their forces in the most detailed and in-depth inspections, aims to provide the world of structural engineering the possibility of working remotely, away from the structure under examination, on images collected in a complete, accurate and three-dimensional images from drones or other automated tools and on which, with the support of A.I. algorithms, the defects have already been annotated and the criticalities are evident.

The CEA is also the only tool to build the digital history of each structure, collecting and making usable at all times the data from the past (original design, end-of-construction as build and material test documents, inspections carried out over the years) and the present, through the automated inspections: all referred to the 3D model of the structure, in which the constituent elements and defects are uniquely positioned and georeferenced.

The CEA is an indispensable tool for today’s engineers, so that they can dedicate their resources, their time, their teams and their skills to the final risk assessment, through the rapid and through analysis of defects annotated on thousands of images, conducted with the support of A.I. and not only with human eyes.

Our Mission

Develop data-enhanced digital model of infrastructures, to assess their conditions, optimize maintenance and prioritize future investment

.1 The sector shows a large set of infrastructure that requires inspection monitoring (e.g., ~350k km of bridges in Europe, ~100k km of bridges in the US).

.2 There is an high need for routine inspection (~40% of bridges in the US has exceeded 40 years, ~10% >80 years vs useful design life of 50-70 years).

Owners, designers and consultants are now planning large renewal programs, with:

Priority

HAS IT TO BE THE FIRST ONE?

REAL URGENCY

NOW OR TOMORROW?

EFFICIENCY

MATERIALS, TIMING OR COSTS?

A.I. can assist structural engineers in managing the huge quantity of data coming from images detection through Unmanned Aircraft Systems (UAS) or tracked robots, can easily trace structure defects and proceed to a deep analysis, adding information coming from on-site visit, design reports and weather monitoring.

Our Vision

Supporting Civil Engineers in Civil Asset Management

We are living an increase in frequency of inspection in critical infrastructure, driven by ageing as well as environmental action due to climate change (e.g., catastrophe-related events such floodings, long-term drivers such as increased rainfall).

Traditional inspections are deficient in quality, and expensive.

Here below some of the reasons:

.1Process of inspection is variable: reports consistency is often extremely variable, depending on each individual, on-site visit quality depends on time spent, bias and seniority of the inspector, lack of systematic and adhered to process lay the ground for bias or poor execution.

.2Historical data may be incorrect or incomplete: the As-Built may differ from the As-Designed, e.g., changes in construction not reported on design/project, original designs and/or drawings might be lost or damaged.

.3Data may not be easily accessible / analysable: data may be difficult to access / searchable, across several documents in PDF formats (when digitized) or paper documents, evolution of conditions not typically tracked systematically and consistently.

.4Expensive: high costs related to inspection equipment (e.g., bybridge) and safety regulation, and much time and experienced people required for in-depth inspection.

OUR IMPACT

The software CEA supports structural engineering, enhances the processing capabilities of engineers and the management capabilities of asset owners, which can never replace the purely human ability to comprehensively assess the health and safety of a bridge, of a tunnel, of a dam, of a building.

SOFTWARE DEVELOPMENT

PROJECT MANAGEMENT

OUR PEOPLE

Board of Directors

TEAM

TECHNICAL ADVISORY BOARD

WANT TO JOIN OUR TEAM?

We are a select group of people with very diverse backgrounds, led by a senior board of directors with hundreds of experiences in software development, structural engineering, and growing and running businesses. All this makes the KnowCE environment truly unique, do you want to be a pioneer with us?